3D Printing, a competitor for the conventional manufacturing processes (i.e., manufacturing by material removal), is the process of additive manufacturing where the manufacturing is done by adding layers of material with a binder in between.

Theoretically, the process is simple – the desired products are designed in design software (eg.Autodesk Inventor) with required dimensions and saved as STL (stereolithography) file. The STL file is then directly fed onto the 3D Printer for manufacturing.

The newer design and optimization software tools like Solidthinking Inspire and Evolve are making it even easier for the designer to quickly create and validate conceptual design which are friendly for 3D additive manufacturing printers.

Available Technologies for 3D Printing

ASTM standardized the 3D Printing technologies into 7 Categories:

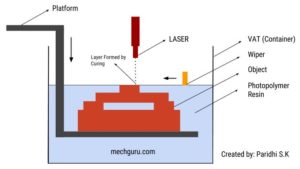

1. VAT Photo polymerization (Invented in 1986 for 3D Systems)

VAT- the Container

Photo polymerization: Creation of bonds using Light (UV)

Steps Followed:

The Container (VAT) is filled with photo polymer resin.

1. Platform Descends @ .05 mm per second.

2. Laser projects light on the resin which cures to form solid according to the STL File loaded.

3. Wiper moves across cross section and re coats the material freshly.

4. Repeat step 1 until the product is completely printed.

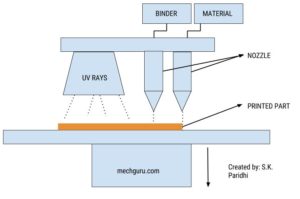

2. Material Jetting (eg. Stratasys’ Objet500 Connex 3D )

It is similar to inkjet printer used nowadays.

The Material and the binder is stored in 2 Cartridges which is injected through a nozzle.

UV rays are used to cure the material.

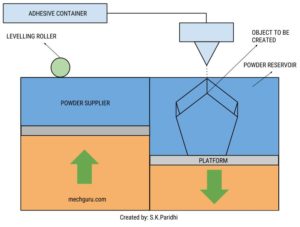

3. Binder Jetting ( MIT invented this technology @ 1993, whereas Z Corporation commercialized this @ 1995 )

Material: Powder

Binder : Liquid

The Adhesive is dropped on the powder above the platform

The Powder from the left reservoir is sent to the right and the platform moves down slowly.

A Levelling Roller is rolled on it.

The Powder becomes hard similar to sintering and the desired object is obtained.

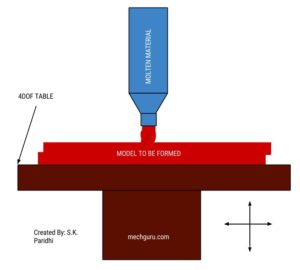

4. Material Extrusion ( 1980 :: It is used by Stratasys )

Molten Material is send through the nozzle.

The Platform has 4 Degrees of Freedom (4 DOF).

The Platform is moved according to the model desired to be created.

Note: Since the material is molten, no binder is required.

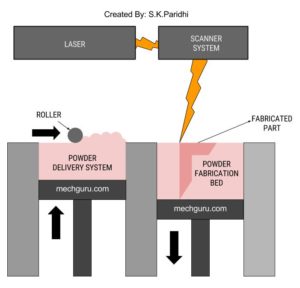

5. Power Bed Fusion ( 1980 :: Invented by Dr. Carl Deckard )

The Technology used in this process is Selective LASER Sintering (SLS).

The metal powder is converted to solid by fusing the powder with LASER.

It uses a High power laser for fusing powder into solid.

After the scanning, the Bed is lowered accordingly.

Then a layer of new material is spread by roller and it continues as a cycle.

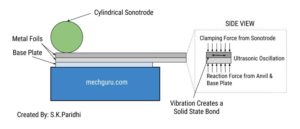

6. Sheet Lamination ( Mcor technologies uses this method)

In this process a Ultrasonic Sonotrode is used to give the Vibration for upper metal foil.

The Lower metal foil Experiences a reaction force and thereby a solid state bond is formed between the two metals.

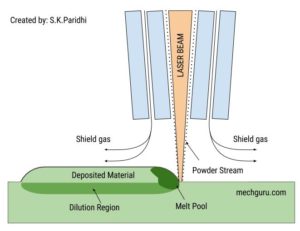

7. Direct Energy Deposition.( Sciaky is one of the Company which uses this method )

LASER is projected on to the work piece which creates a fusion/molten region.

Power Stream is projected on to the molten region to create the additive region.