I am amazed by the pace at which not only the additive manufacturing hardware and machines but also the simulation software for 3D printing are evolving.

Given the fact that the whole 3D printing industry itself still is in its adolescence, if not in childhood, it’s quite interesting to see how different software vendor is trying to capture the real process of 3D printing.

The concept of simulation driven optimized design, which I am evangelizing as part of my profession, goes very well with Design for Additive Manufacturing (DAFM). It’s quite interesting to note that not many of the first mover in this AM process simulation space are not actually the CAD/CAE biggies.

Here is what I found as far as the metal powder based laser melting processes are concerned:

Amphyon by AdditiveWorks: I got chance to do some initial hands on with this tool. The capability that hooked me up with this tool is its solver speed and process assessment option, by which you can quick optimize your build orientation .

The assessment stage allows users to do a tradeoff (what if) study of different AM parameters such as build orientation, support volume, distortion etc.

Virfac by Geonx: VIRtual Factory (VIRFAC) has the complete manufacturing simulation suite, additive manufacturing is one of them.

From the preliminary I could found that it has very vast material models as well as different scale (micro, Meso, Full) of process level targeted to capture the metal additive manufacturing physics accurately.

Simufact Additive: Its again a complete suite of manufacturing simulation software and additive manufacturing is one among them.

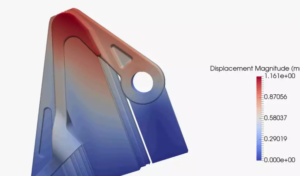

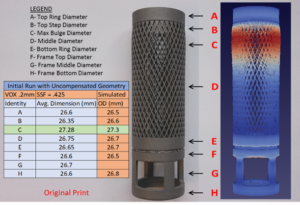

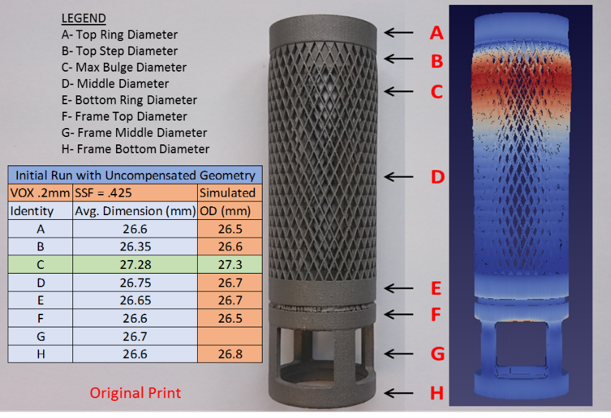

You will be able to predict distortions, residual stress and support material volume.

ExaSIM by 3D Sim: ExaSIM is a cloud based metal laser sintering additive manufacturing simulation software.

Other than predicting residual stress and distortions, It can generate support structure based on the distortion patterns.

This is going to be a dynamic article, and I will keep updating it as and when I found some input on the subject. Signing off for now, Looking for your comments.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )

Dear Sir, I need your guidance for my FDM project. Actually I want to make machine learning model for prediction and simulation of FDM printed parts.