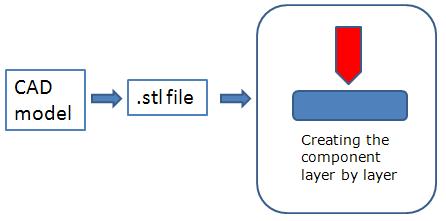

Rapid prototyping or 3D printing is the manufacturing process for creating the components by layer wise deposition. The process starts with creating a 3D CAD model of the component to be produced. The CAD file is then converted to .stl (Stereolithography) file. The specialty of the .stl file is it stores the geometry details of the cross sectional layers of the component. A 3D printing machine then used for creating the component based on the cross sectional geometry data.

Advantages:

– Complex shape can be produced

– Good for manufacturing at conceptual stage

– No custom tooling required

Disadvantages:

– Only limited numbers of materials can be used

– Costly process

Ideal applications: Suitable for making prototype out of the plastic and other easily meltable materials.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )

Additional advantages of using cad & rapid prototyping is the ability to make incremental changes to your design and reproduce quickly. Often we get multiple orders for the same part because a left angle should have been a right angle. It is much less expensive to do these changes in the prototypes than in a production tool.

Bill Bounds