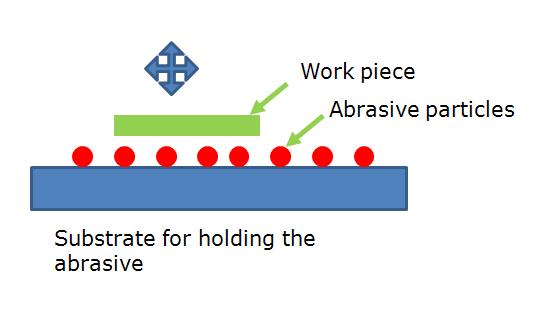

It is a surface finishing process. The basics of lapping process is moving the work piece surface (to be finished) very slowly against some sort of abrasives. The abrasives can be either loosely spread over a hard substrate or rigidly glued over the substrate surface. Also, the process of lapping can be either performed manually or by using a machine.

Level of surface finish achieved: 0.8-0.012 micro meters

Advantages:

– Variety of materials can be chosen

– Great surface finish

– Tight tolerance can be achieved

Disadvantages:

– It is a slow process

Ideal applications: Ideal for making surface specimens for metallurgical testing.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )