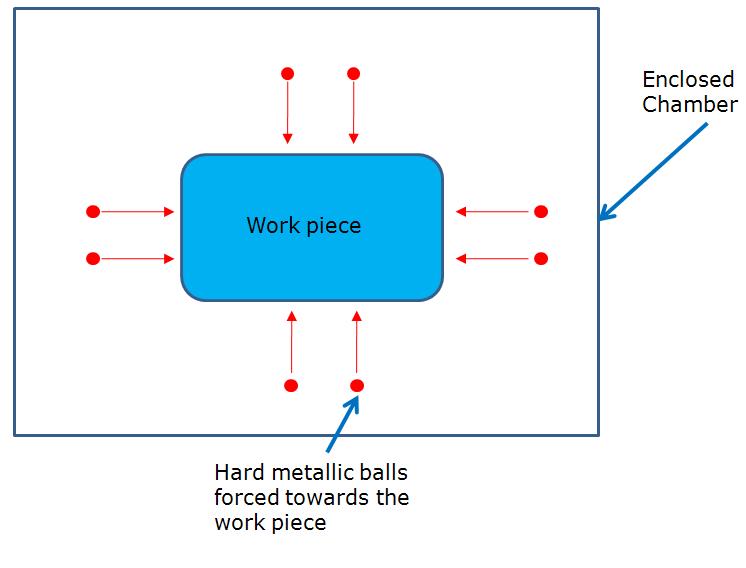

In Shot pinning, hard metallic balls are shot at high speed all over the exposed surfaces of the component by keeping the component at an enclosed chamber. The same metallic balls are sucked back and recalculated again and again. The repeated beatings by the hard balls make the surface smoother. The main purpose of this process is to relieve the stresses and to clean up the surfaces.

Advantages:

– Good fatigue strength

– Case porosity reduction

Disadvantages:

– High equipment costs.

– The process must be precisely controlled to achieve the desired results,

Ideal applications: Casting components are normally shot blasted to clean it up.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )