Since CNC machine is basically a computer controlled manufacturing machine, so, the basic checklist for buying any production machines also holds good for purchasing CNC equipment as well. To make the basic checklist customized for buying computer numerically controlled equipments, some more points must be added. This article will talk about those additional points in details (somewhat), but before that let me explain in short how typically it works.

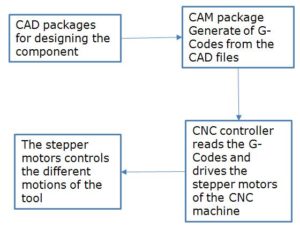

How CNC Machine Works

The above flow chart, which I feel self explanatory, is describing the overall working of the computer numerical controlled machines.

1. CNC Milling or Router or Something else

- If your application is machining 2D parts like cutting a profile of a plate or something like that, then a CNC plasma cutting machine or a water jet would be sufficient and efficient enough for you.

- If you want to machine on soft materials like wood, particle board, plastic or something similar and you don’t need very complex (in terms of number of dimensions) then you can go for a CNC router machine.

- In case you want to machine hard metals like steel or similar then CNC milling equipment will be your need.

2. 2-Axis, 2.5-Axis, 3-Axis or more

- A 2-axis machine is capable of producing the cut profile out of a plate. For example, if you want to produce a gasket like plate, 2-axis is suitable for you.

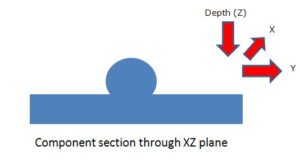

- 2.5-Axis machine actually capable of moving all the 3 directions (X, Y, Z) but not together. Only towards two of the directions it can move together. For example, if you have a component like below:

Then a 2.5-Axis CNC machine won’t be able to machine it for the reason that the tool has to move in all the three directions together in order to cut the curved semi circular profile. You will require at least a 3-Axis machine in this case.

- Now see if the component cross section looks like below:

Please observe in the above figure (Fig.2), the circular cross section is projected more than half over the surface. In this case a 3-axis won’t be sufficient; you will require a 5-axis machine here.

3. Work piece size

This is a common math; you must select your machine based on the maximum and minimum component size you are looking to produce.

4. Rate of production

This parameter is important for you to decide whether you need to go for a separate CAM program or not. If you are looking for small production rate then the inbuilt CNC GUI will be sufficient for you to feed the G-Codes manually or else you have to purchase a separate CAD/CAM system.

5. Controllers

The following lists will give you the most popular names of CNC machines, CAM softwares and controllers.

- CNC manufacturers: Mazak, Star, Citizen, Haas, DMG, FADAL, Tsugami, Index, Tornos, Hardinge, and ROBO Drill etc.

- Controller program developers: Fanuc, Okuma, Siemens, mach, EMC (free), Bendix, Dynopath, Autocom, Hurco, Julious Gertz, Yasnac, Okuma, Mazatrol, Fadal, Heidenhain, and Haas etc.

- CAM Software developers: MasterCAM, SolidCAM, ArtCAM, Vectric, rhinocam, meshcam, camworks etc.

The aim of providing the above list is not only to give you an idea about the popular options available in the market but also to warn you about the incompatibility issues. Make sure that your existing CAM system is compatible with your new CNC machine because all the different controllers run on slightly different dialect of the G-codes.

In case I missed something, you feel important for purchasing a CNC, please leave a comment.

Grate post! Thank you for sharing this interesting and valuable blog. Keep us inform like this.

I admire your blog. It good and interesting blog to read. Thank you for sharing this valuable blog. Keep us inform like this.

Nice post. Such an interesting and helpful parameters which you mention in this blog. Thank you for sharing this.

You have shared very helpful tips for buying machines ,This information is very attractive and supportive parameters which you mentioned in this post.

Himes Machinery

You have shared very helpful tips for buying machines ,This information is very attractive and supportive parameters which you mentioned in this post.

Himes Machinery

You have shared very helpful tips for buying machines ,This information is very attractive and supportive parameters which you mentioned in this post.

Himes Machinery

Nice post… But their so many other factors need to consider before buying Plasma Cutting machine. For more details on this please visit http://www.zlobber.com/resources/11077-Factors-Consider-While-Buying-Plasma-Cutting-Machine-Its-Benefits.aspx