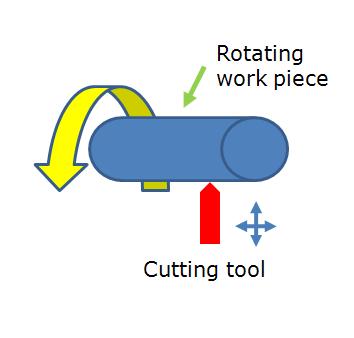

In turning process, a single point cutting tool (normally made up of HSS) is used for removing materials from a fast rotating work piece necessarily by using a machine called lathe.

Level of surface finish achieved: 25-0.025 micro meters

Advantages:

– Variety of materials can be chosen for turning

– Lead time is shorter

– Tight tolerance can be achieved

Disadvantages:

– Large scrap wastage

– Limited to axis-symmetric circular cross sectional components

– Equipment cost is quite high.

Ideal applications: Ideal for producing different types of shafts and similar axisymmetric components made up of mild steel, stainless steel, copper, aluminum etc.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )