This article will describe the end to end process and machines required for plywood manufacturing. Follow the next ten steps to understand how plywood is typically manufactured :

Step-1: Cutting the logs

The large wooden logs, normally stored under water are cut into pieces according to the production requirement.

Tools/Machinery required: Large hand saw or machine saw (Saw mill).

Siep-2: Processing the logs

The pieces of the logs are then heated at around 70-90 degree C temperature for 12-14 hours either under hot water or in a steam chamber.

Tools/Machinery required: Steam chamber or hot water bath.

Step-3: Debarking

The bark or the thick skin around the log is removed either by hand tools or by using a debarking machine.

Tools/Machinery required: large chisel and hammer or debarking machine.

Step-4: Veneer making

Veneers are the few millimeters thick layers of wood of. The veneers can be made either by peeling or by slicing. The log is to be loaded to a peeling lathe or a slicer machine for making veneers out of it.

Image courtesy: Dr. P.D.Evans

Tools/Machinery required: Wood peeling lathe or veneer slicing machine.

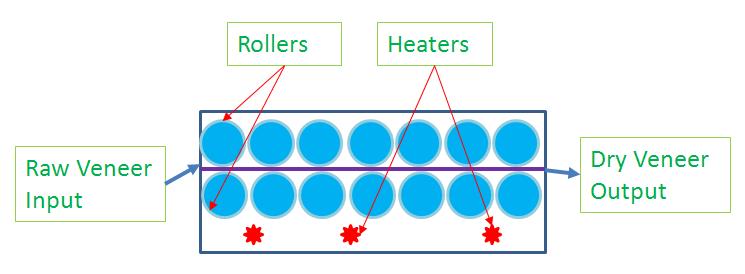

Step-5: Wet Clipping The veneer then cut into pieces of required sizes by using a clipping machine. The clipping machine works like a big scissors. Tools/Machinery required: Veneer clipping machine. Step-5: Drying The veneers are then dried partially by sunlight and partially by a dryer machine. Maintaining required amount of moisture in veneers is very important for producing the good quality plywood.

Tools/Machinery required: Veneer dryer, Veneer moisture meter.

Step-6: Dry Clipping After drying again the veneers are clipped using the clipping machine. This step is required to cut the veneers in close tolerance and to remove the drying defects.

Tools/Machinery required: Veneer clipping machine.

Step-7: Resin preparations Either liquid or the powder resins are used for making glue. Urea formaldehyde (UF) and phenyl formaldehyde (PF) are the two most common types of resins used in plywood manufacturing. In case of liquid resin, the resin is manufactured normally in house by using a resin kettle or resin plant.

Tools/Machinery required: Resin plant or kettle.

Step-7: Gluing and assembly The correct sized veneers are then glued normally by using a gluing machine. The veneers are passed in between two rollers of the gluing machine. The rollers of the gluing machine are kept wetted by the continuous supply of glue. The odd numbers of veneer layers are assembled such a way that the grain directions of the consecutive layers are perpendicular to each other.

Tools/Machinery required: Veneer gluing machine.

Step-8: Hot pressing The assembled veneer layers are transferred inside the hot hydraulic press which apply specific pressure and temperature for specified duration of time to the veneers assembly and convert it to plywood by curing the resins.

Image courtesy: Wiki

Tools/Machinery required: Hydraulic hot press

Step-9: Trimming The circular power saw is used for trimming the plywood boards to give it the required size.

Tools/Machinery required: Circular power saw

Step-10: Inspection, labeling and dispatching Inspection is performed to find out the rejected and reparable pieces among the good pieces. The reparable pieces are repaired using putty and color pastes manually. Finally labeling and dispatching is done.

Tools/Machinery required: Labeling machine.

This is how typical plywood manufacturing process and machinery goes, if you have anything to share on the subject please feel free to comment.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )

i want to detail knowledge about plywood manufarer unit and how many budget required

If you are really serious about gaining knowledge for starting plywood manufacturing unit in india, you can get training and know how from Indian Plywood Industries Research and Training Institute, Bangalore (www.ipirti.gov.in/)

What are the types of cutting knives / blades used in the playwood making process?

Hello everyone, can anyone tell me what kind of manufacturing process is used for plywood? (jobbing, batch, line etc) Cheers

Hello everyone, can anyone tell me what kind of manufacturing process is used for plywood? (jobbing, batch, line etc) Cheers

What are some steps in processing plywoods

there are two ‘step 7’s

I want to detail knowledge about plywood manufacturer unit and how many budget required

I want to detail knowledge about plywood manufacturer unit and how many budget required of machine + plant + civil work

we want a second hand plywood making machine from your company .please let us know the prise

I required the details of manufacturing process of flexible plywood my unit at Gujaratpp