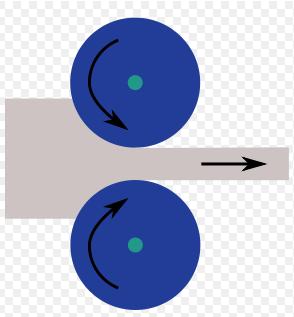

Cold rolling is the process of giving shape to the soft raw materials by passing it through a set of rollers without applying heat (or, more technically, below recrystallization temperature). To make the raw material soft, annealing is normally done before this process. The components produced by this process have good surface finish and tighter tolerances. However, the component produced by this got work hardened and you should do normalizing before performing any further machining on it. Normally multiple rolling stations are used for gradual reduction of the cross sections.

Image source: Wiki

Level of surface finish achieved: 6.3-0.20 micro meters

Advantages:

– Good surface finish

– Good dimensional accuracy

– Cost effective process

Disadvantages:

– Cannot change the shape drastically.

– Require annealing before rolling.

Ideal applications: Ideal for making strips, sheets, bar, rods.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )