The static and kinetic friction coefficient values reference table shown in this article will be helpful for finding the COF values of commonly used materials.

Static and Kinetic coefficient of friction

Image Source: Wiki

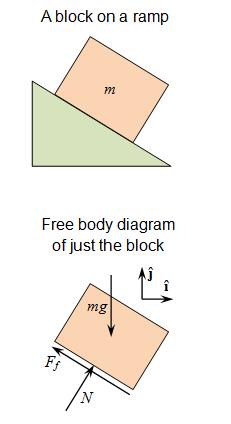

Both the types of COF can be expressed by the same equation as below (refer with the Fig.1):

μ= Ff/N………………Eq.1

Where,

Ff – Frictional force along the surface

N – Normal reaction perpendicular to the surface.

μ – Coefficient of friction between the block and the surface, for Static friction it is termed a μs and for kinetic or sliding friction it is termed as μs or μk .

Then what is the difference between static and kinetic friction coefficient?

For static COF the block must be in static or non-moving condition, i.e., you have to take the friction force value of the force which is applied to the block for giving motion to it but the force value has not yet reached to the limit that can move the block.

For sliding or kinetic friction coefficient, you have to consider the friction force value of the moving block.

Friction Coefficients table

| Material-1 | Material-2 | Coefficient of static friction ( µs) | Coefficient of sliding friction ( µk) |

| Aluminium (Al) | Aluminium (Al) | 0.42 | 0.34 |

| Aluminium (Al) | Copper (Cu) | 0.28 | 0.23 |

| Aluminium (Al) | Steel | 0.35 | 0.25 |

| Aluminium (Al) | Titanium | 0.34 | 0.29 |

| Aluminium (Al) | PTFE | 0.19 | |

| Aluminium (Al) | Teflon | 0.19 | 0.18 |

| Aluminium (Al) | Chromium (Cr) | 0.27 | 0.22 |

| Aluminium (Al) | Nickel (Ni) | 0.33 | 0.25 |

| Aluminium (Al) | Mild Steel | 0.61 | |

| Aluminium (Al) | Glass | 0.17 | 0.14 |

| Aluminium (Al) | Graphite | 0.16 | |

| Brake Material | Cast Iron (Fe) | 0.40 | |

| Brass | Cast Iron (Fe) | 0.3 | |

| Brass | Steel | 0.35 | 0.24 |

| Brass | Glass | 0.2 | |

| Bronze | Titanium | 0.36 | 0.27 |

| Bronze | Ice | 0.02 | |

| Bronze | Cast Iron (Fe) | 0.22 | |

| Bronze | Steel | 0.16 | |

| Cadmium (Cd) | Cadmium (Cd) | 0.79 | |

| Cadmium (Cd) | Cast Iron (Fe) | 0.52 | |

| Cadmium (Cd) | Mild Steel | 0.46 | |

| Cobalt | Cobalt | 0.56 | |

| Cobalt | Chromium (Cr) | 0.41 | |

| Cobalt | Cast Iron (Fe) | 0.41 | |

| Cobalt | Lead (Pb) | 0.55 | |

| Chromium (Cr) | Chromium (Cr) | 0.46 | |

| Chromium (Cr) | Cobalt | 0.41 | |

| Chromium (Cr) | Cast Iron (Fe) | 0.48 | |

| Chromium (Cr) | Nickel (Ni) | 0.59 | |

| Chromium (Cr) | Lead (Pb) | 0.53 | |

| Chromium (Cr) | Alumina | 0.50 | |

| Chromium (Cr) | Zerconia | 0.61 | |

| Chromium (Cr) | Teflon | 0.09 | 0.08 |

| Chromium (Cr) | Aluminium (Al) | 0.27 | 0.22 |

| Chromium (Cr) | Steel | 0.25 | 0.21 |

| Copper (Cu) | Copper (Cu) | 0.55 | |

| Copper (Cu) | Cobalt | 0.44 | |

| Copper (Cu) | Chromium (Cr) | 0.46 | |

| Copper (Cu) | Cast Iron (Fe) | 0.5 | |

| Copper (Cu) | Nickel (Ni) | 0.49 | |

| Copper (Cu) | Zinc | 0.56 | |

| Copper (Cu) | Aluminium (Al) | 0.28 | 0.23 |

| Copper (Cu) | Silver | 0.48 | |

| Copper (Cu) | Steel | 0.32 | 0.25 |

| Copper (Cu) | Stainless Steel | 0.23 | 0.21 |

| Copper (Cu) | Teflon | 0.13 | 0.11 |

| Copper (Cu) | Zinc | 0.56 | |

| Cast Iron (Fe) | Cast Iron (Fe) | 0.51 | |

| Cast Iron (Fe) | Cobalt | 0.41 | |

| Cast Iron (Fe) | Chromium (Cr) | 0.48 | |

| Cast Iron (Fe) | Manganese (Mn) | 0.51 | |

| Cast Iron (Fe) | Molybdenum (Mo) | 0.46 | |

| Cast Iron (Fe) | Titanium | 0.49 | |

| Cast Iron (Fe) | Zinc | 0.55 | |

| Cast Iron (Fe) | Lead (Pb) | 0.54 | 0.43 |

| Cast Iron (Fe) | Steel | 0.4 | |

| Cast Iron (Fe) | Tin (Sn) | 0.55 | 0.32 |

| Gold (Au) | Gold (Au) | 0.49 | |

| Gold (Au) | Silver (Ag) | 0.53 | |

| Gold (Au) | Lead (Pb) | 0.61 | |

| Graphite | Graphite | 0.18 | 0.14 |

| Graphite | Aluminium (Al) | 0.16 | |

| Graphite | Steel | 0.18 | |

| Graphite | Glass | 0.15 | |

| Glass | Aluminium (Al) | 0.17 | 0.14 |

| Glass | Steel | 0.13 | 0.12 |

| Glass | Teflon | 0.1 | 0.1 |

| Glass | Brass | 0.19 | |

| Glass | Steel | 0.13 | 0.12 |

| Glass | Glass | 0.9 | |

| Silver (Ag) | Silver (Ag) | 0.5 | |

| Silver (Ag) | Gold (Au) | 0.53 | |

| Silver (Ag) | Copper (Cu) | 0.48 | |

| Silver (Ag) | Cast Iron (Fe) | 0.49 | |

| Silver (Ag) | Lead (Pb) | 0.73 | |

| Silver (Ag) | Alumina | 0.37 | |

| Silver (Ag) | Zirconium | 0.39 | |

| Steel | Steel | 0.31 | 0.23 |

| Steel | Titanium (Ti) | 0.48 | 0.48 |

| Steel | Nylon | 0.35 | |

| Steel | Teflon | 0.27 | 0.27 |

| Steel | ABS | 0.3 | 0.35 |

| Steel | PVC | 0.53 | 0.38 |

| Steel | Chromium (Cr) | 0.25 | 0.21 |

| Steel | Glass | 0.13 | 0.12 |

| Steel | Graphite | 0.18 | |

| Titanium Vanadium alloy (Ti-6Al-4V) | Titanium Vanadium alloy (Ti-6Al-4V) | 0.36 | 0.3 |

| Titanium Vanadium alloy (Ti-6Al-4V) | Bronze | 0.36 | 0.27 |

| Titanium Vanadium alloy (Ti-6Al-4V) | Steel | 0.36 | 0.31 |

| Titanium Vanadium alloy (Ti-6Al-4V) | Aluminium | 0.41 | 0.38 |

| Titanium Vanadium alloy (Ti-6Al-4V) | Chromium | 0.38 | 0.33 |

| Silicon Carbide (SiC) | Silicon Carbide (SiC) | 0.52 | |

| Silicon Carbide (SiC) | Silicon Nitride (SiN) | 0.53 | |

| Tungsten Carbide | Tungsten Carbide | 0.22 | |

| Tungsten Carbide | Steel | 0.45 | |

| Tungsten Carbide | Copper (Cu) | 0.35 | |

| Tungsten Carbide | Cast Iron (Fe) | 0.8 | |

| Teflon | Chromium | 0.09 | 0.08 |

| Teflon | Nickel | 0.15 | 0.12 |

| Teflon | Aluminium (Al) | 0.19 | 0.18 |

| Teflon | Glass | 0.1 | 0.1 |

| Teflon | Steel | 0.18 | 0.16 |

| Teflon | Titanium Vanadium alloy (Ti-6Al-4V) | 0.23 | 0.21 |

| Ice | Ice | 0.01 | 0.01 |

| Ice | Bronze | 0.02 | |

| Leather | Metal | 0.61 | 0.25 |

| Leather | Wood | 0.61 | 0.52 |

| Wood | Wood | 0.25 | 0.129 |

| Wood | Brick | 0.6 | |

| Wood | Metal | 0.3 | |

| Wood | Concrete | 0.61 | |

| Wood | Snow | 0.14 | |

| Brick | Wood | 0.6 | |

| Paper | Paper | 0.28 | |

| Bitumen or Asphalt (Wet) | Rubber | 0.25 – 0.75 | |

| Bitumen or Asphalt (dry) | Rubber | 0.9 | 0.5 – 0.8 |

| Concrete (Dry) | Rubber | 0.6 – 0.85 | |

| Concrete (Wet) | Rubber | 0.45 – 0.75 |

Although, reliable sources (mentioned at the reference section) has been used for compiling the above COF table but still the values shown are approximate only. The friction coefficient value changes not only with material but also with the position and orientation of the participating materials. So, if you need accurate COF value, you must obtain it by experiment only.

Reference

- ASM-VOL 18-FRICTION, LUBRICATION AND WEAR TECHNOLOGY

- Friction Science and Technology FROM CONCEPTS to APPLICATIONS – By Peter J. Blau

Nothing I could say would give you undue cdreit for this story.

What is the coefficient of static friction between silicon and graphite? thank you.

What is the coefficient of static friction between silicon and graphite? thank you.

what would be the static and kinetic COF of PTFE impregnated, hardcoated aluminum on the same. I think the specification limit of 0.15 is too low for this application.

What is the coefficient of static friction between Nylon (Plastic) and Brass? thank you.

How come there is a difference between Steel – Teflon and Teflon – Steel in table above. Or, for example Aluminum – Steel and Steel – Aluminum?

And what about rubber and metal?

what is coeffient of friction between bitumen and concrete.

static coefficient of friction with nylon and mild steel

What about PEEK – Aluminium?

what about Rubber and Aluminium?

What about zirc alloy and steel

What is the sliding COF of non oily based hessian fabric on satin finished stainless steel, dry conditions?

Hi..thank you for this helpful information. Could you please share the reference as well?