High pressure die casting or HPDC

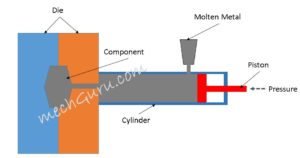

Block diagram of HPDC process is shown below, molten metal is poured into the cylinder where the piston force the molten metal to flow into the mould cavity.

Once the poured metal inside the mould cavity get cold and take shape the die halves got opened and the moulded component come out. And the process continues.

Low Pressure Die Casting or LPDC

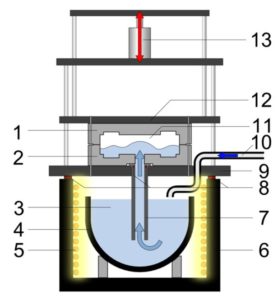

Working of LPDC process is explained through the block diagram below:

Here, the molten metal (3) is forced by the pressure of gas passed through the pipe (10) into the mould cavity (11) against the gravitational force. Once the mould cavity is sufficiently filled and the component got cooled enough, the die halves (1 &2) got opened and the moulded part got ejected out.

| HPDC | LPDC | |

| Tooling Cost | High | Low |

| Equipment Cost | High | Low |

| Production cost / unit | Low | High |

| Production Rate | High | Low |

| Porosity | High | Low |

| Surface finish | High | Low |

| Suitable for | Al & Zi alloys, Component with high surface finish

low fatigue strength: carburetor, distributor bodies, switch gear housing etc. |

Al & Zi alloys, Component with low surface finishhigh fatigue strength: auto wheels, gearbox,

electric motor stator etc. |

hey Prashant,

could you please tell me that what’s the difference between cold die pressure casting and high-pressure casting?