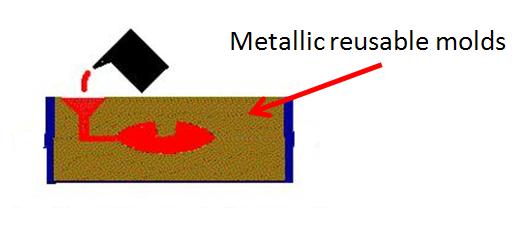

In gravity die casting process, reusable metallic molds are used for creating the mold cavity where molten metal are poured without applying any force or pressure other than gravity. A silicate based coating is sprayed over the inner surface of the mold cavity before pouring the molten metal.

Level of surface finish achieved: 3.2-0.40 micro meters

Advantages:

– Good surface finish compare

– Low cost setup

– Waste can be recycled

– Quick cycle time

Disadvantages:

– Suitable for simple components

– Chances of defects are high

Ideal applications: Suitable for producing aluminum alloy and other similar light metal components. This process gives smoother surface than sand casting.

I had some difficulty viewing the site in Safari on the Mac, but I still loved the site

Good article keep it up and thanks share with us

we manufactures

Gravity Die castings

Compared to gravity casting, low pressure

casting offers following advantages: In air mass gravity die casting

manufactures, the metal at intervals the chamber is ironed through the riser

tube into the mould by pressure that works on the metal surface .This form of

mould filling is that the most significant distinction to gravity and tilt-able

casting. The method of mould filling yield fully controlled. This ends up in a low-turbulence or perhaps turbulence-free mould filling.