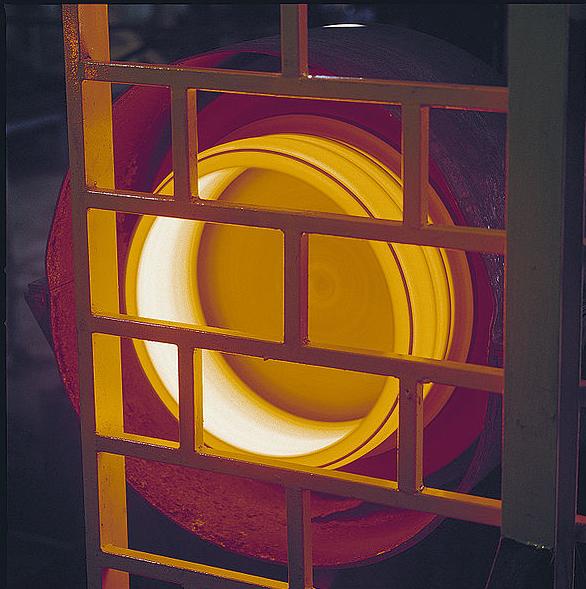

In centrifugal casting process, the tubular and axi-symetric components are produced by revolving the mold at high speed (300-3000 rpm) about its own axis while pouring the molten metal into the mold cavity.

Image source: wiki

Level of surface finish achieved: 3.2-0.40 micro meters

Advantages:

– Low tooling costs

– Very less wastage.

Disadvantages:

– Lower mechanical strength.

Ideal applications: Suitable for manufacturing cylinders, liners, sleeve valves, flywheels made up of iron, steel, glass, aluminum, copper and nickel.

Animation of centrifugal casting process http://www.gibsoncentritech.co.uk/animation.htm