Here, we will discuss the material selection process for the mechanical design of the following three basic types of structural members:

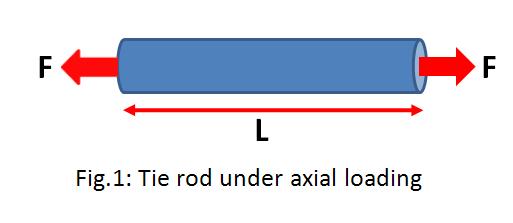

a) Circular cross section tie-road under axial loading

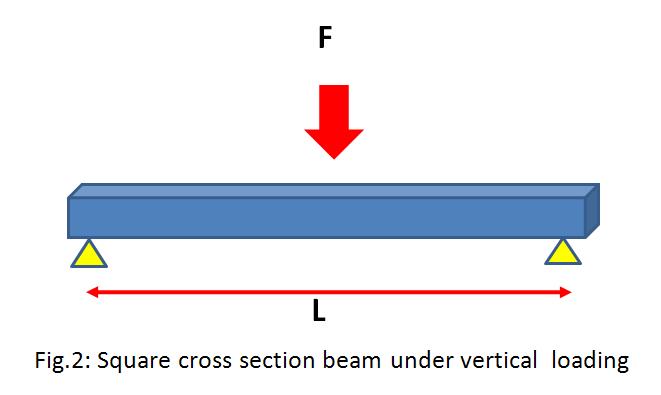

b) Square cross section beam under vertical loading

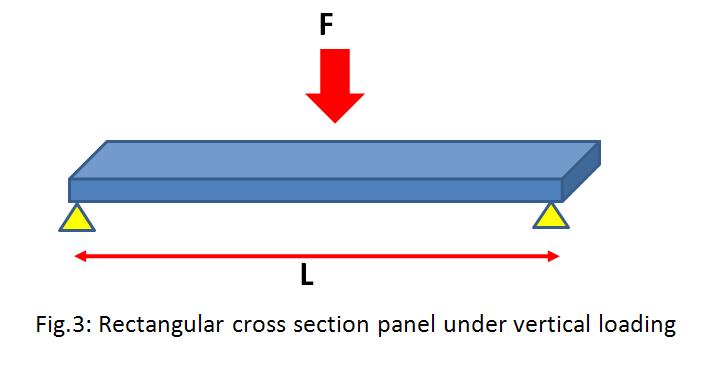

c) Rectangular cross section panel under vertical loading

Of course, the real life design problems are very much complicated, but I think these basic examples are the building blocks for the complicated problems.

a) Material Selection Guide for Circular Cross Section tie-road Design

- F – Axial force

- L – Length of the tie-rod

- A – Cross section area of the tie rod

- δ – axial deformation of the tie road

- d- density

- s- stress

- m – mass of the tie rod

- E – Modulus of elasticity

We have the following two basic equations:

δ =LF/AE……………………………..eqn.1

m=AL/d…………………………….eqn.2

From the above two equations, we can write:

m= (L2F/ δ) (d/E)…………………..eqn.3

As a designer, our aim is to minimize the mass of the tie rod and to achieve that we have to minimize the quantity (d/E).

So, for the design of tie rod under axial loading the material with minimum (d/E) has to be chosen.

b) Material Selection Guide for Square Cross Section Beam Design

- F – Axial force

- L – Length of the beam

- b – Length of one side of the cross section area of the beam

- δ– Deflection of the beam

- d- Density

- s- Stress

- m – Mass of the beam

- B – Stiffness of the beam

- I – Area moment of inertia for the beam

- K – Constant

- E – Modulus of elasticity

We have the following two basic equations:

B = F/ δ = KEI/L3=KEb4/12L3……………………………..eqn.4

m= b2Ld……………………………………..…………………..eqn.5

Combining the above two equations we get

m = (12BL5/K)1/2(d/E1/2)………………………………eqn.6

So, in case of designing the beam under vertical loading for achieving the minimum mass, we have to minimize the quantity (d/E1/2) .

c) Material Selection Guide for Rectangular cross section

- F – Axial force

- L – Length of the beam

- b – Width of the panel

- t – Thickness of the panel

- δ– Deflection of the beam

- d- Density

- s- Stress

- m – Mass of the beam

- B – Stiffness of the beam

- I – Area moment of inertia for the beam

- K – Constant

- E – Modulus of elasticity

We have the following two basic equations:

B = F/ δ = KEI/L3=KEbt3/12L3……………………………..eqn.7

m= btLd……………………………………..…………………..eqn.8

Combining the above two equations we get

m = (12Bb2/K)1/3(d/E1/3)L2………………………………eqn.9

So, in case of designing the panel under vertical loading for achieving the minimum mass, we have to minimize the quantity (d/E1/3).

Material selection for mechanical design in case of tie-rod emphasis on the quantity (d/E), in case of designing the square beam the quantity of importance should be (d/E1/2) and in case of rectangular panel the quantity of importance should be (d/E1/3). Once, as a mechanical designer you are able to find out the material selection parameter, you can use the material selection tool or software like CES for actually selecting the most suitable material for your application. I will discuss the different steps required for using CES in my next article.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )

When are you going to do your next article ?

Next article ?

excellent article

….send next…soooooooooooooon

excellent article please upload next soon..

and sir I think your second equation wrong.

it should be m=d*A*L

then only third is possible