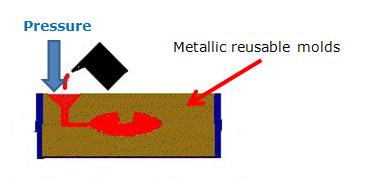

Unlike gravity die casting, squeeze casting process require pressure or force to be applied on the molten metal to push the molten metal to fill the heated metallic mold cavity. The applied pressure helps proper filling of the molten metal even at the narrow remote corner areas. The pressurized molten even helps to get rid of air trapping.

Level of surface finish achieved: 12.5-0.40 micro meters

Advantages:

– Good surface finish

– Less porosity

– Less post casting operation required

– Good strength due to finer micro structure.

– Very less wastage.

Disadvantages: – High tooling and equipment cost

Ideal applications: Suitable for small complex shaped mass produced by aluminum alloy and other similar light metal components.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )