This theory also known as maximum distortion energy theory, shear strain energy theory or octahedral shear stress theory.

The detail study shows that it is the shear strain energy rather than shear stress which is the main culprit behind yielding of ductile materials.

What is strain energy?

Consider the case of a spring, if you pull it, it will absorb some energy and will try to come back to its normal shape and size by realizing the absorbed energy. So, the energy stored in body due to change in its shape or volume within elastic zone is called strain energy.

What is shear strain energy?

Consider a case of a cube; if you apply unequal stress in all three directions, then the volume as well as shape of the cube will change. The energy stored in the body due to change in volume is called volumetric strain energy and the energy stored in the body due to shape change is called shear strain energy.

What von mises criterion says?

It says that yielding will occur when shear strain energy or distortion energy of unit volume will exceeds the shear strain energy of the same volume subjected to uni-axial stress by yield strength.

We know that equation of strain energy (volumetric plus shear) is:

Uσ = 1/2E [(σ12 + σ22 + σ32 )-2υ(σ1 σ2 + σ2 σ3 + σ3 σ1 )]……Eqn.1

In order to get pure shear strain energy out of this equation we have to subtract the volumetric strain energy components from this.

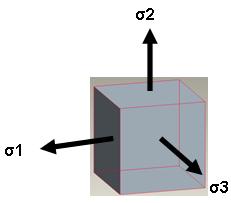

Now, look at the figure of the cube below:

This is the initial situation when three unequal stress σ1, σ2 and σ3 is applied to the cube , pure volumetric stress component out of these unequal stress σ1, σ2 and σ3 is :

σav = ( σ1+ σ2 + σ3 )/3

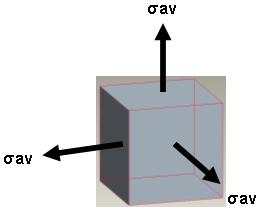

How? If you apply σav in all the three direction like below:

then you will see that there will be only volumetric strain, means there won’t be any change in angles between the faces, i.e., no shear strain. So, in Eqn.1 if we substitute σ1, σ2 and σ3 by σav then we will be able to obtain the strain energy component related to volumetric strain. Thus volumetric strain energy equation obtained from Eqn1. will be:

Uv = 3 σav2 (1-2υ)/2E ………………….Eqn.2

Then by putting σav = (σ1+ σ2 + σ3)/3 and subtracting Eqn.2 from Eqn.1 we will get the distortion energy (shear strain energy):

Ud =Uσ – Uv =(1+ υ )[( σ1– σ2)2 +( σ2– σ3)2 +( σ3– σ1)2 ]/6E ….Eqn.3

Remember the von mises criterion, which says that this Ud should be less than distortion energy (say Ud’ ) at , σ1= Sy (yield strength at uniaxial tensile condition) and σ2 =σ3 =0. By putting these values at Eqn.3 we will get :

Ud ‘ =(1+ υ ) σ’ 2 /3E …………………………Eqn.4

So, from Eqn.3 and Eqn.4 as per von mises criterion, the body will start yielding when :

Sy <= [(σ1– σ2)2 + ( σ2– σ3)2 +( σ3– σ1)2 ] 0.5/√2…………………Eqn.5

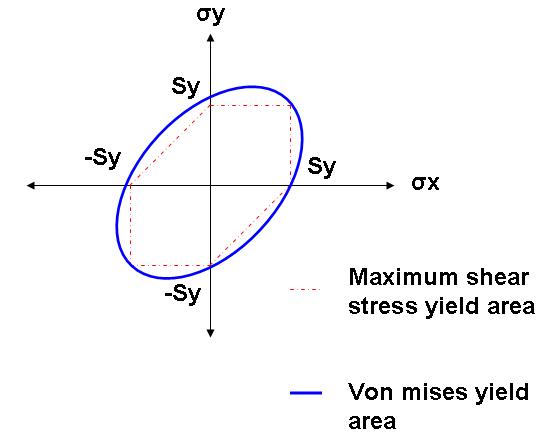

In the above figure both von mises as well as shear stress yield area has been shown. The significance of these areas are , in order to satisfy the respective failure criteria the values of respective principle stress should be within the respective curve. You will also notice from the figure that the maximum shear stress criterion is bit more conservative than von mises criterion.