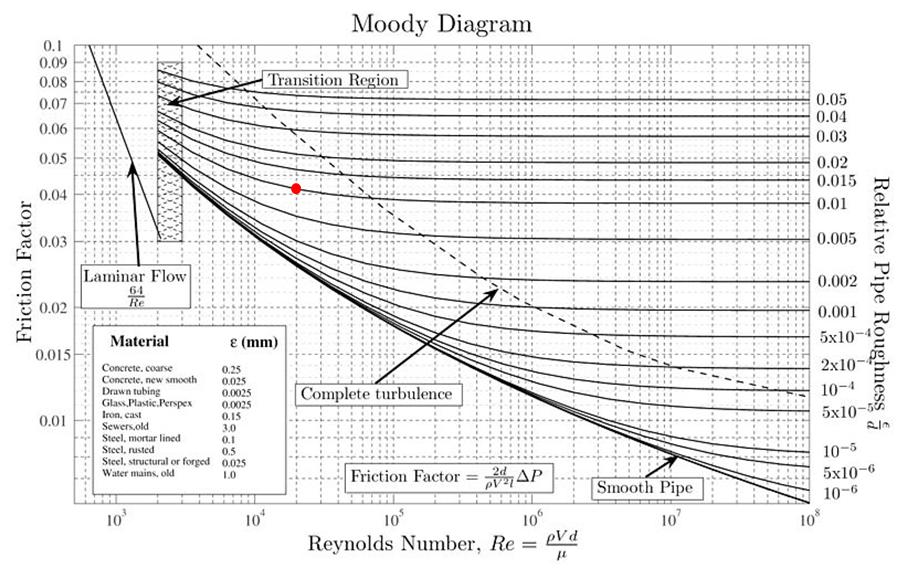

Moody friction factor will be used as another input for the D’arcy-Weisbech equation which is used for calculating the final pressure drop of the piping system design calculation example. The Moody’s factor can either be calculated by using Colebrook equation or by using Moody diagram. We will use the diagram for finding out the friction factor value for our water pipe sizing calculation example problem.

Image Source: Wiki

How to Read the Moody Diagram

- Find out the curve most closely matching with your relative roughness value.

For our example problem, we already found out the value of the relative roughness in Part-5 as 0.0075. So I will use the 6th curve (0.01) from the top.

- Find out the intersection point of the relative roughness curve and the calculated Reynolds number.

For our example problem, we already calculated the value of the Reynolds number in Part-6 as 35592.84. I have marked the approximated intersection point for our example by red dot in the above Moody chart.

- Draw a horizontal line from the intersection point towards the friction factor axis to find out the approximate friction factor value. Adjust the friction factor value according to the difference between the actual relative roughness value and the relative roughness curve you have selected initially.

For our example, the approximate Moody friction factor value is coming around 0.04. And after adjusting the final friction factor comes to 0.035.

In the next part (Part-8) of this piping sizing calculation tutorial we will use the D’arcy-Weisbech equation to find out the final pressure drop.

hi, i can access the part 8, can you please help

sorry, i mean i can’t access the part 8, please help

Hi, doesn’t the red dot indicate a Reynolds number of 2x10E4? For a Reynolds of 3.6x10E4, shouldn’t the red dot be located halfway between 1x10E4 and 2x10E4? Also, with adjusting the final value of the friction factor, if 0.035 is the actual friction factor value, wouldn’t this correspond to the relative roughness of 0.005 (instead of 0.0075 in the question)? The friction factor I got for Re = 3.6x10E4 and relative roughness = 0.0075 is around 0.04. Am I correct?

[WORDPRESS HASHCASH] The poster sent us ‘0 which is not a hashcash value.