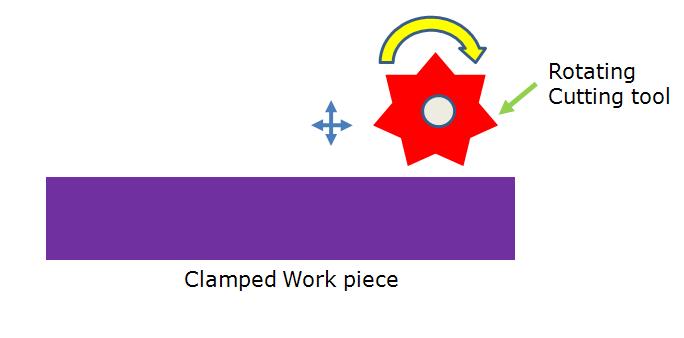

Milling is the layer by layer materials removing process from the work piece. The process is carried out at milling machine by using specially made rotating cutting tools. The work piece remains stationery and the cutting tool moves along the three directions (X, Y and Z). Cutting fluid or coolant is normally used while performing the milling operations.

Level of surface finish achieved: 25-0.20 micro meters

Advantages:

– Variety of materials can be chosen

– Lead time is shorter

– Tight tolerance can be achieved

Disadvantages:

– Large scrap wastage

– Equipment cost is quite high.

– Tool wear is quite high.

Ideal applications: Milling can be used for producing vast range of component like planning a surface, making key slots, creating tapered surface, creating gear tooth .

You’ve relaly captured all the essentials in this subject area, haven’t you?