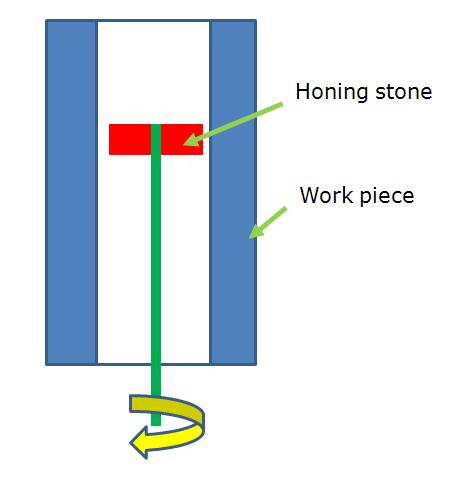

The honing process is carried out by mechanically rubbing the honing stone (cutting tool here) against the work piece surface (normally internal) along the controlled path. Honing can produce a surface roughness level up to 0.1 micro meters.

Level of surface finish achieved: 1.6-0.025 micro meters

Advantages:

– Variety of materials can be chosen

– Good surface finish

Disadvantages:

– Equipment cost is quite high.

– Tool wear is quite high.

Ideal applications: Ideal for finishing the internal surfaces of I.C engine cylinders, hydraulic cylinders and other cylinders where retention of lubricants film over the surface is important functionally.