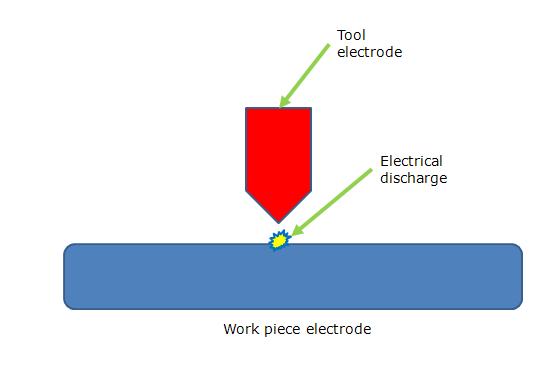

EDM is the material removal process by means of electrical discharge. Typically, the tool (either a wire or a probe) consists of one electrode and the work piece is another electrode. The work piece is sometimes immersed into the non-conducting dielectric liquid to increase the potential difference between the two electrodes. The gap between the electrodes are maintained such that electric discharge can happen after certain voltage and by the process work piece gets eroded locally to generate the cut.

Level of surface finish achieved: 12.5- 0.8 micro meters

Advantages:

– Very good surface finish can be achieved

– Hard brittle materials can be machined

– Suitable for very delicate and week materials as well

– Complex profiles can be created

Disadvantages:

– Very slow rate of operation

– High power consumption

– High tool wire

– Normally not suitable for non conducting materials.

Ideal applications: The electrical discharge machining is suitable for generating complex profile with tight tolerances for extremely hard electrically conduction materials.

Hi, I am Shibashis, a blogger by passion and an engineer by profession. I have written most of the articles for mechGuru.com. For more than a decades i am closely associated with the engineering design/manufacturing simulation technologies. I am a self taught code hobbyist, presently in love with Python (Open CV / ML / Data Science /AWS -3000+ lines, 400+ hrs. )