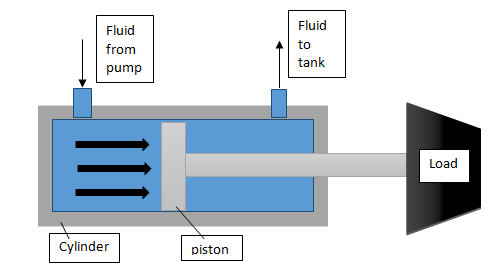

What is hydraulic cylinder?

The hydraulic cylinder is a device that converts the energy of fluid into mechanical energy. The fluid is pumped into the cylinder by means of a pump and it can be used to move a load. The size of the cylinder determines the amount of load that can be handled by it.

Major parts of a hydraulic cylinder

- Piston

- Cylinder

In this tutorial we will discuss how to do the design or sizing calculation for piston. Cylinder design will be explained elsewhere.

Design calculations for hydraulic piston

The calculation of size of the hydraulic cylinder consists of two steps:

Step 1: calculation of the area of cross section of the piston

A = F/P……………..eq.1.1

Where, A is the area of cross section of the piston

F is the force acting on the piston

P is the pressure of fluid supplied by the pump.

Step 2: calculation of diameter of the piston

D = √(4A/ Π)………..eq.1.2

Where, D is the diameter of the piston

A is the area of cross section of the piston.

Solved example

Consider a load of 1000 N required to be pushed by a hydraulic cylinder and the fluid is pumped at a pressure of 2 N/mm2. Find out the required piston size.

Solution:

Step 1: First find the area of cross section required:

A = F/ P

= 1000/2

= 500 mm2

Step 2: Calculate the piston diameter

Dp = √(4A/Π)

= √(4*500/3.14)

= 25.23mm

Thus the size of the hydraulic cylinder piston size can be determined. The piston size is an important input parameter for calculating the internal diameter as well as wall thickness of the hydraulic cylinder.

For the sake of simplicity we will consider the internal diameter of the cylinder is equal to the diameter of the piston for further calculation.